Bangalore! Bangalore!!Bangalore!!! . Twice i have missed chances to go there.. The last missed chance was when i had invested a full weekend in planning out the probable travel outings after my presentation ends.. But due to unforeseen reasons.. I missed that opportunity.

Being a an Engineering Student and that too in the Electrical Engineering School , one never gets time to visit places too often ( Thing only an Engineer can understand ).

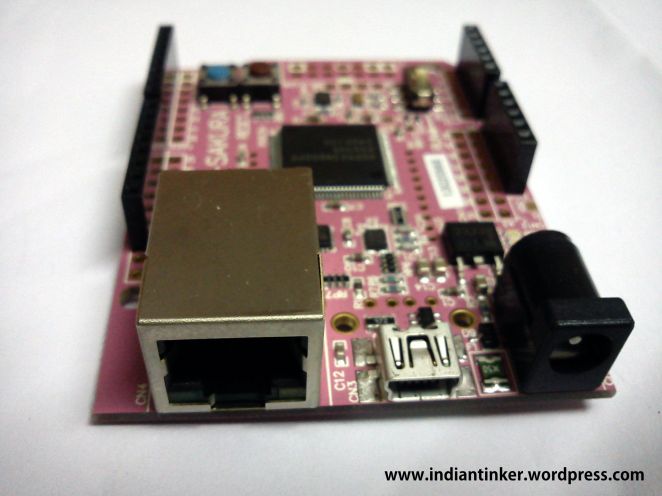

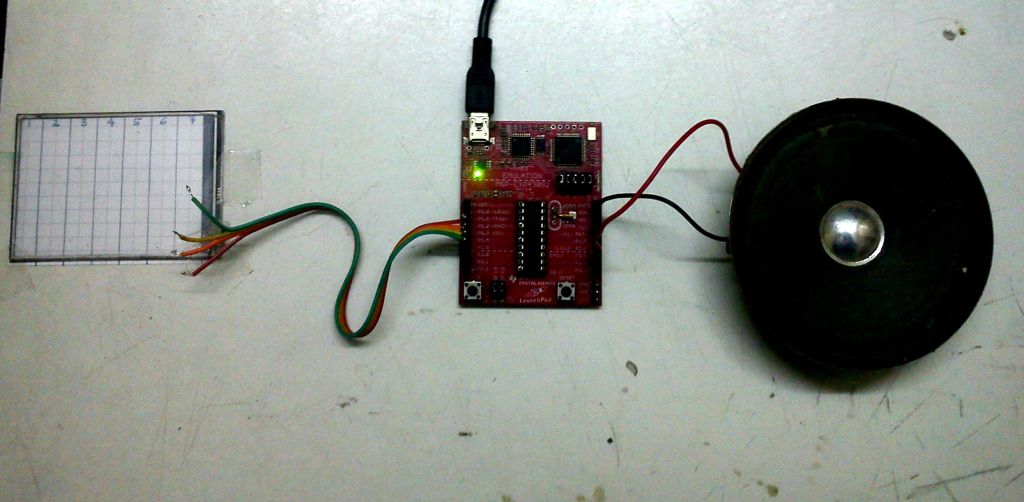

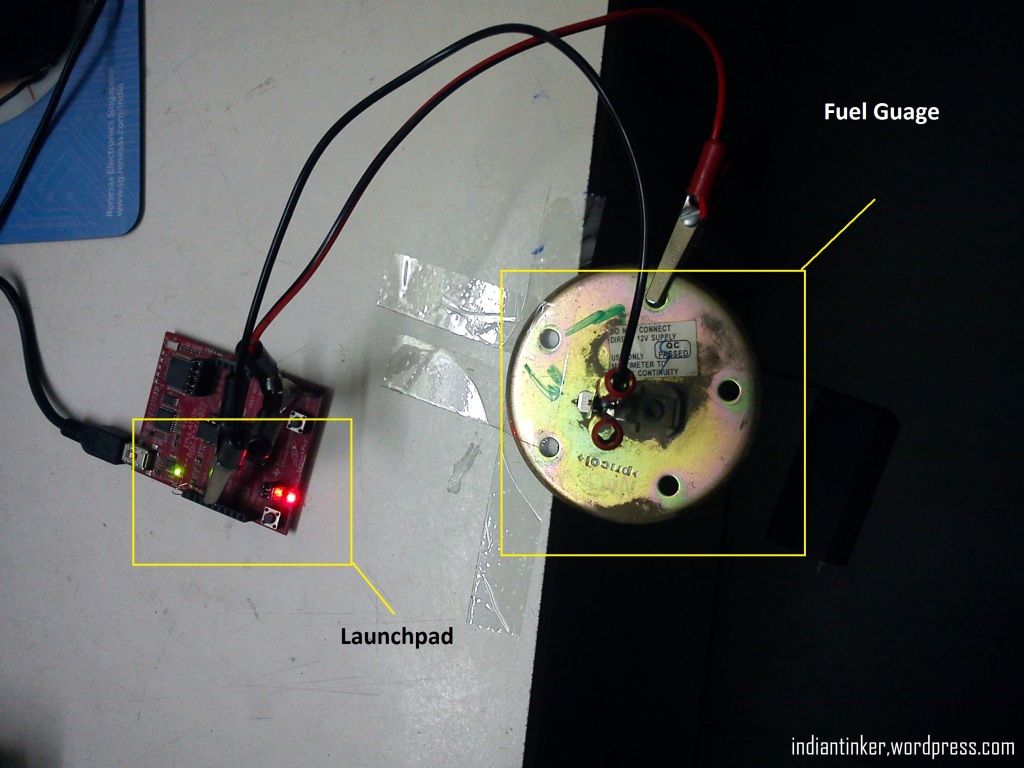

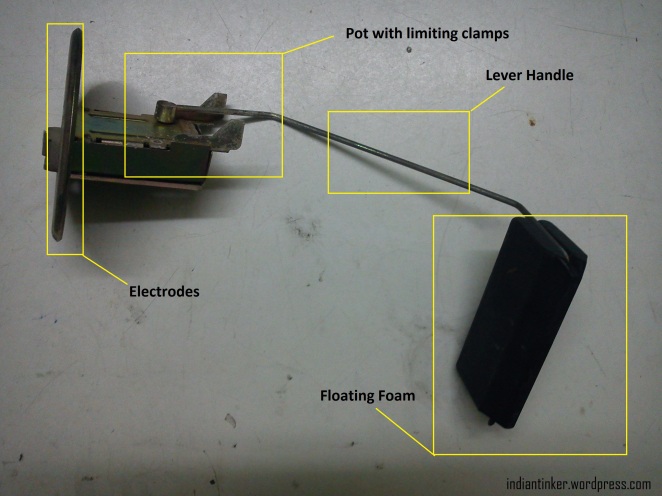

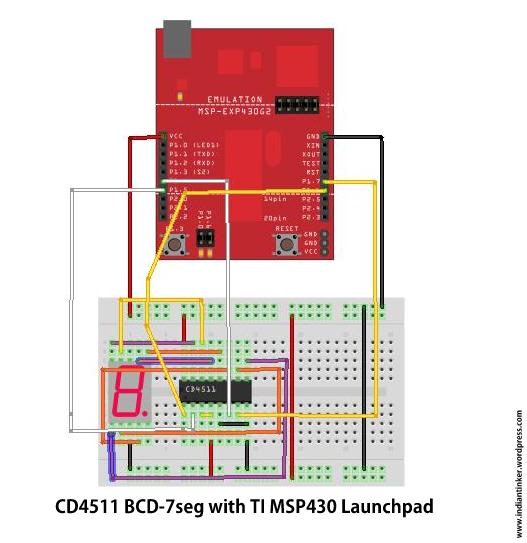

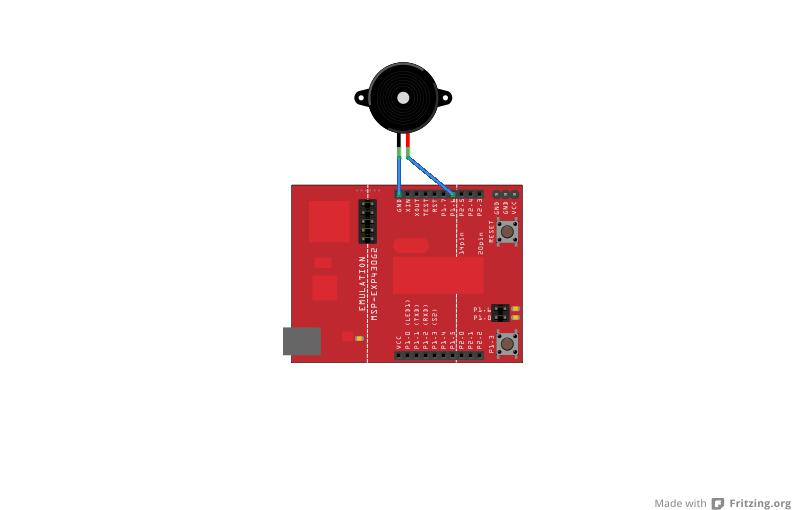

Long story short, I and my friend [Jaspreet] had made a project for TI-ADC 2012-2013 which ultimately got selected as ‘Consolation Prize Winner’. You can see the project video that we submitted here . Basically it was initially developed to log the data from our solar car and display it on the GUI wirelessly. Not only that we can switch many loads inside the cars like fans and lights but also we can monitor and control everything except the driver! We scaled up the project into a multi-nodal sensor system. The use of it is that we now don`t need to wire these units physically. The GUI does that entirely!

Micro-Nodes!

As consolation prize winners we had to present the paper at TIIEC-2013 and demonstrate the project at NIMHANS Convention Centre,Bangalore! At about the same time, another college team of [Shashank a.k.a Shank] and [RohitKrSingh a.k.a RKS], our juniors also made it to the Consolation stage with their Autonomous Ship Navigation System. It was great!! Now we all had to reach bangalore. The possible ways was by train or air! Train took a hell lot of time ( almost 2 days) and plane took just 2 hours. So we booked Air Tickets and We were soon on board Spicejet SG-211 !

All the participants will be grateful to TI as they had arranged accommodation for two in an awesome IBIS Hotel,Hosur Road , All meals, all travel and were even reimbursing us train tickets.. In the mean time ,since we had planned to visit and roam around in Bangalore and maybe visit Mysore we need accommodation for an extra 2 days.. Since we wont be staying in the hotel after the conference we needed some alternative place.. I ringed some relative and cousins in Bangalore and finally got us an accommodation for the next 2 days! I also made some city roaming plans in my little diary. I had heard that Public Transport connectivity is pretty good in Bangalore and one should refrain from taking the “AUTOS” . So , i noted all the major route and at least 3 alternative routes with bus numbers in case Google Maps ditched me! ( more on this later)

Sambhar Dosa- Not like the one we get here in Delhi.Chutney and Sambhar served in equal qty.

Conference was great! We talked with a lot of like minded people from across our country and made new friends , learned some “Marathi” from the team we shared our booth with. Their description of the marathi songs we heard in some TV shows was enlightening !

It was the best exhibition i had attended and the best part was that our booth was the first of all, nearest to the gate. So , everyone would first come to our booth. [Jaspreet] did all the explaining most of the time. I was mostly roaming here and there, asking others exhibitors about their stuff ( Courtesy: Restlessness ).

I would be great to bring the fact that the Conference was inaugurated with an electronic lamp which is a project i was involved in.You can read about it here!

In between the conference after the day got over, i had to make a quick run to my aunt and the case was same for [RKS]. Apparently the route was pretty much the same. We had planned that all four of us will go, but that did`nt panned out . So, only two of us were going at their respective aunts. We walked to the Bomanahalli bus stand waited for like 40 mins. It was 9pm and none of the buses google said i could get, were coming.. Further, the place where my aunt stayed was kadubesanalli. I repeatedly kept saying it to the drivers/conductors and they all made faces like ” What the hell?? Is that a place , in around here? “.I found out i was pronouncing it very badly. Finally at 9:15 pm a bus came and a passenger said that go to the “Silk Board” and catch the bus. No bus goes directly from here.

We went to silk board and got the bus!

MISSION ACCOMPLISHED! The buses were great, very clean and with an air conditioner that was really effective! Reaching at my aunts place was not difficult after that. We returned at about 12 that night and crashed on the bed to go to the conference the next day!

I presented my first paper and then the next day was the Awards night!

Now, we had planned to roam around for the next two days! The IBIS Hotel offered us extended luggage vault this saved us a lot of miles else we would have to run to my brother about 20km away and that would cost us quite a part of the day.

As suggested, we took the One Day AC bus Pass ( Which i have secure in my ‘Ticket Collection’ ). As planned we would go to Banerghatta Park to watch some animals, then go to a couple ( which ultimately came down to one! ) museums. It was Saturday and roads to park was packed! The AC bus driver was playing local songs in Kannada ( i guess). The other passengers were enjoying it.. It was alien to me but i enjoyed the tune..

The bus conductor dropped us about 1.5km before the entrance of the park. I still don`t know why as the bus was there at the park when we reached. As we walked towards the entrance, we saw a group of “Art Of Living” volunteers on a cleaning mission, we shopped some drinks and local “namkeens” (which i am really fond of tasting where ever i go) and at last reached the gate. Then, i turns out there are several options and ways to browse the park, we went with the most common one that is normal bus with cage like windows! If somebody happens to have been to Borivali National Park, the bus is pretty much the same! But the catch is that you have to occupy the seats in order of your entry to the bus and they are hell strict about it.The Park is very well maintained and its not allowed to take any plastic stuff inside the park and the guard on the gate packed all the “namkeens” i had bought into separate paper bags!

Phew! We happened to be at the last one and we got the back seat and also there were lesser people so, we could choose, Right or Left??

We ended up on the Left Side ( which was an awful choice as it turns out later ). The bus started, everybody got their shooters out . There are separate areas( bigger than those as in Borivali National Park ) for lions, tigers,bears, deers and elephants! The bus driver would stop at every place from where we could see any animal. This time we were in the cage and animals were in open. You can check out the pictures below and have a look at all the animals we saw. The bad thing happened on that particular day all the animals choose to come on the right side and we could hardly see then with all the people busy finding their niche in those 7 windows of the bus !  . But thankfully [jaspreet] and [rks] chose the right side and they could click some pics which we rejoiced later!It was pretty hot that day, most of the animals were either in water or near water .

. But thankfully [jaspreet] and [rks] chose the right side and they could click some pics which we rejoiced later!It was pretty hot that day, most of the animals were either in water or near water .

After the bus ride got over, we were left like in the middle of nowhere , A walk with the other people on the bus, ended up at the ButterFly park! It is a good place to visit and has a lot of nasty butterflies roaming inside the specially prepared bio-dome for them which creates the right amount of humidity for them to survive. There is also a museum about the butterflies which we quickly breezed through. We saw a lot of people bringing macro lens clad DSLR to click those tiny restless butterflies. Wonder how they (butterflies ) felt about the photo session (Random Thought !) 😀

Here are some we manage to catch in our CMOS-CCD!

Having spent the day, in such a wonderful way was just great! To make it better, we wanted to go it HAL Museum which was pretty far. So, we boarded the Bus , which dropped us at Richmond and then we boarded another bus to HAL Museum. The stomach was ringing hunger bells but it can be ignored for a while as the museum entry closed at 5pm and it was already 4pm. We had to hurry! Fortunately the bus came in about a minute and we were on the way to the HAL Museum. But this time again, even after mentioning to the conductor that we needed to go to the “MUSEUM”. He dropped us 2.5km before. With the time not on our side and no bus stop near we had to walk..walk..walk..walk. During, the walk we saw some great labs (from the outside ) like Shape Memory Alloy Lab and Metal Workshops also. Being students of engineering the very sight of “Textbook” words written on laboratory doors was pretty spell-bounding and assuring that what we are studying is not fiction.

So, we reached the Museum all drenched in sweat and thankfully the doors were open. We got in.. We saw a PSLV Heat shield (used/recovered/prototype ) in which the satellites are protected during the launch!

Heat Shield Inside!

There are several real models of planes used in Indian Airforce and they are pretty well presented. Apart from that there is a whole museum of circularly arranged chambers which show Indian History as far as Aeronautics is concerned. We were blessed by the presence of [RKS] who in my eyes is the mobile wikipedia of Aeronautics. The moment he say a name plate which may be of an engine , ejection system or the plane.. He would tell us about the history and specifications of the engine and all such details which none of the display boards mentioned. It is a great place for someone who is interested in seeing planes.

We spent close to an hour in the museum and then we were back at Mc`Donald`s for feasting! We then boarded the bus back to IBIS Hotel (actually a couple of buses) to get our luggage and move to JNCASR,Jakkur where my brother was waiting for me!

Ah! What a day spent after a wonderful conference!

We had plans for Mysore the next day! Catch it in the next edition i.e Travelogue: Mysore!

Stay Tuned!